The results of the preliminary simulation are achieved through computational models that are commonly used in the field. The purpose of the preliminary simulation is to prove the progressive trends in the CoAxial engine performance rather than commitment to precise values.

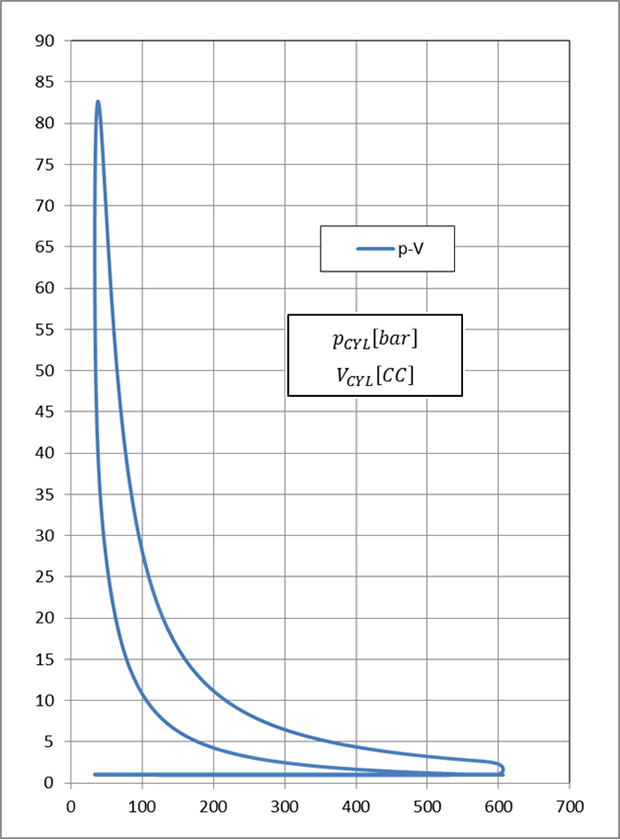

For instance, the first chart shows that the shape of the p-V curve corresponds to a gasoline engine but it actually represents diesel thermodynamic cycle. And the reason for this abnormality is the prolonged piston dwelling around the TDC which is totally affordable for the unique CoAxial engine kinematic.

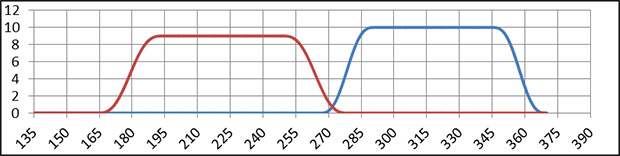

It is notable also in the same chart that the pumping losses are unusually low during the fluid exchange phases. The second chart, valve timing and lift, provides immediate explanation for that. The valves open/close faster and stay longer in their top position than usual. Of course the valves motion laws have to be synchronized with the pistons ones in order to get optimal minimization of the pumping losses.

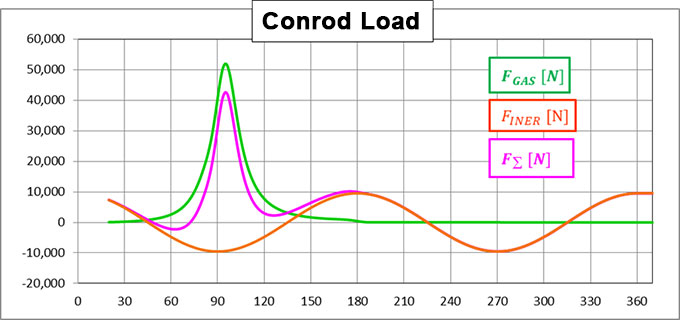

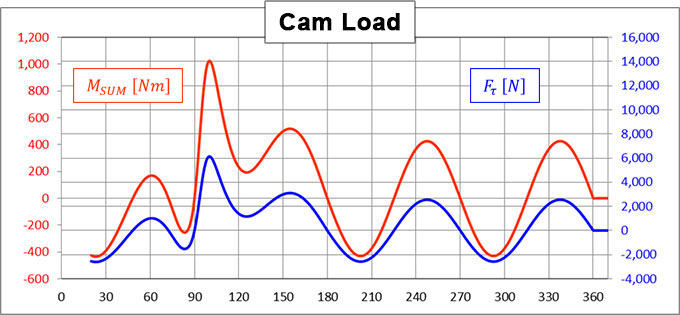

The present simulation allows also to estimate the CoAxial engine vital components life. The accuracy is believed to be within 10%. But even in the worst case scenario, the life spans of the components are pretty decent. Besides, the CoAxial engine life could be easily improved through variation of the basic engine parameters such as bore diameter, stroke, cam diameter and so on because they are more independent between each other than those belonging to the conventional ICE.

| DESCRIPTION | VALUE | UNIT |

|---|---|---|

| BORE | 90.0 | mm |

| STROKE | 90.0 | mm |

| NUMBER OF CYLINDERS | 1 | – |

| SWEPT VOLUME | 573 | cm3 |

| COMPRESSION | 18.00 | m3/m3 |

| SPEED | 1200.0 | RPM |

| INDICATED OUTPUT | 8.9 | kW |

| INDICATED OUTPUT TORQUE | 71.1 | Nm |

| INDICATED EFFICIENCY | >55 | % |

Valve Timing & Lift (mm)

← SMALL PUMPING LOSSES

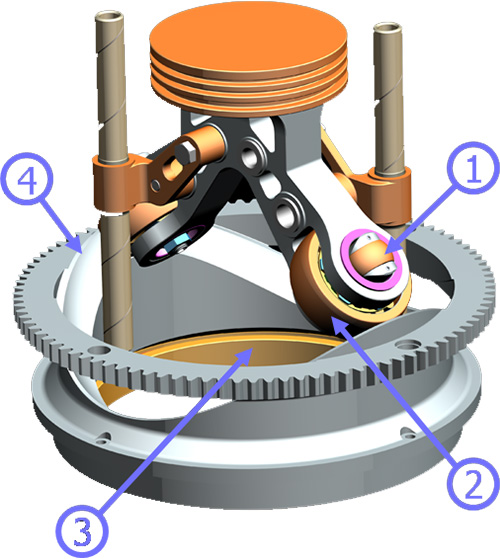

| BEARINGS LIFE – BASIC – L10h | L10h [h] |

|---|---|

| 1. ADD. ROLLER BEARING LIFE | 10,150 |

| 2. MAIN ROLLER BEARING LIFE | 14,077 |

| 3. CAM BEARING LIFE | 7,035 |

| 4. CAM PROFILE LIFE | 9,896,860 |